Previous

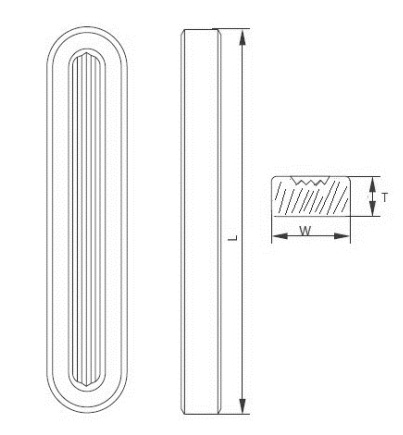

Borosilicate Reflex Gauge Glass

The reflex gauge glass is made from borosilicate glass, with low coefficient of thermal expansion, good thermal stability and chemical performance.

The side facing the medium chamber is provided with moulded grooves set at 90° angles. The moulding process increases the resistance of the glass groves to wear; the ‘’skin‘’ which the glass attains during moulding gives it maximum smoothness and hardness.

This makes it extremely resistant to the attack of boiler water.

The quality of gauge glass depends on its chemical composition, mechanical strength, dimensional accuracy.

Bending strength is determined by the surface compressive stress and the inherent resistance of the glass. The inherent resistance is heavily dependent upon the

surface quality.

Technical characteristics

Working temperature: 400°C

Pressure: Max 4Mpa

Bending strength: standard level gauge glasses ≥120Mpa

Chemical resistance

Alkali resistance: alkali class 2, tested to DIN ISO695

Water resistance: tested to DIN ISO719-HGB1

Acid resistance: acid class 1, tested to DIN ISO1776/DIN12116.

Application

Widely used for observation of vessels (tanks/boilers/industrial oven/liquid level gauge), chemical processing, water engineering, oil refineries and marine engineering etc.

Packing

The glass is packed in individual white box, cardboard case.

Dimension (mm)

Size | Type A | Type B | ||||

Length(L) | Width(W) | Thickness(T) | Length(L) | Width(W) | Thickness(T) | |

Ⅰ | 115 | 30 | 17 | 115 | 34 | 17 |

Ⅱ | 140 | 30 | 17 | 140 | 34 | 17 |

Ⅲ | 165 | 30 | 17 | 165 | 34 | 17 |

Ⅳ | 190 | 30 | 17 | 190 | 34 | 17 |

Ⅴ | 220 | 30 | 17 | 220 | 34 | 17 |

Ⅵ | 250 | 30 | 17 | 250 | 34 | 17 |

Ⅶ | 280 | 30 | 17 | 280 | 34 | 17 |

Ⅷ | 320 | 30 | 17 | 320 | 34 | 17 |

Ⅸ | 340 | 30 | 17 | 340 | 34 | 17 |